PRODUCTS

- Core Wire and Bar Solders

- Solder Pastes

- BBIEN Solder Powder

- Semiconductor Powder

- Tacky Paste &Epibond Adhesive

- Chemical for Solders

- Special Metal Wire/alloy

- Solder Wick and Tools

- Ribbon Solder

- Mixer Machine

SEARCH

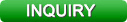

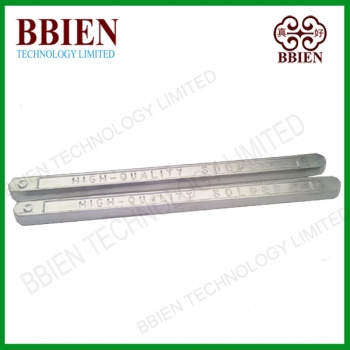

63%Sn37%Pb tin lead alloy soldering bar

63%Sn37%Pb tin lead alloy soldering bar

63%tin 37%lead soldering bar is manufactured using high purity raw materials and is treated using proprietary dross reducing technology to give a solder alloy that has Low Dross Characteristics.

Sn63Pb37 welding bar is manufactured using ultra high purity raw materials and the alloy is conditioned using BBIEN's proprietary viscosity and dross lowering treatments. This results in a pure, low drossing, high fluidity solder alloy, which is free of cast-in impurities and included oxides.

less tin dross and high purity high fluidity solder alloy of 63%Sn37%Pb tin lead alloy soldering bar the excellent welding result bar solders lead solder bar for wave soldering SMT PCB。

|  |  |  |

Feature:

1. Favorable fatigue resistance and outstanding performance

2. Ultra high electrical conductivity

3. Mid-temperature soldering, characterized by nice softness and wonderful wetting property.

4. Benefit from activated rosin core flux.

5. Ultra strong oxygen resistance. Due to the anti-oxygen material in the solder wire,Sn63Pb37 no clean solder wire can give strong resistance to oxygen.

Range of application: widely used for manual soldering or automatic iron soldering operations, applicable to repair or the soldering of the electronic elements of electronic products.

Chemical content:

1. Favorable fatigue resistance and outstanding performance

2. Ultra high electrical conductivity

3. Mid-temperature soldering, characterized by nice softness and wonderful wetting property.

4. Benefit from activated rosin core flux.

5. Ultra strong oxygen resistance. Due to the anti-oxygen material in the solder wire,Sn63Pb37 no clean solder wire can give strong resistance to oxygen.

Range of application: widely used for manual soldering or automatic iron soldering operations, applicable to repair or the soldering of the electronic elements of electronic products.

Low Dross Characteristics:giving cost effective use of the solder alloy.

Low Dross Characteristics:reducing the amount of dross in the wave pot leading to lower downturn and reducing the chance of oxide entrapped in joints.

Manufactured to Alpha’s high standards: giving a product that can be relied on to give good consistent soldering performance.

Low Dross Characteristics:reducing the amount of dross in the wave pot leading to lower downturn and reducing the chance of oxide entrapped in joints.

Manufactured to Alpha’s high standards: giving a product that can be relied on to give good consistent soldering performance.

Chemical content:

| Impurity content % | |||||||||||||

| Sn | Pb | Sb | Ag | Cu | Fe | Zn | Bi | Al | As | Ni | Cd | ||

| 63±2 | 37+/2 | ≤0.10% | ≤0.02% | 0.1% | ≤0.02% | ≤0.001% | ≤0.10% | ≤0.001% | ≤0.03% | ≤0.01% | <0.01% | ||

| 62.5 | 37.5 | 0.032 | 0.0002 | 0.0057 | 0.002 | 0.0015 | 0.006 | 0.0024 | 0.0021 | 0.0032 | 0.0001 | ||

Related Products