Main Characteristics

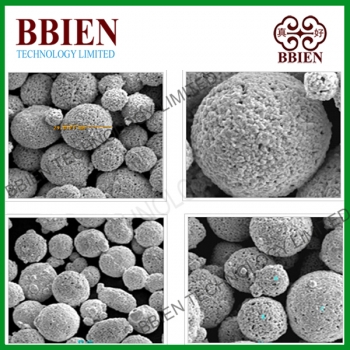

Good solder powder must have the following properties: a “clean dry sand” appearance, a gray-silver color vs. a charcoal-gray, which indicates presence of oxidation and good flow behavior go to functional test. Other important features include high powder density close to the theoretical density of the alloy and no internal voids or external satellites (microspheres attached to a single sphere).

Our BBIEN Technology solder powder products offer:

- Low process temperatures from 190°C to 300°C

- Low pressure sintering of 5-10 MPa or higher

- Consistent print characteristics

- High thermal conductivity silver bond lines ~ 250 W/mK

- Bond lines from 5μm to 100μm

- Dies from <1mm2 to wafers >70,000mm2

- High volume manufacturing capabilities (up to 70,000 uph)

- Lead free and zero voiding

- Long shelf life and easy start up

- Compatible with Multi-chip modules, discretes, cavity packages,stacked dies, lead frames, and more

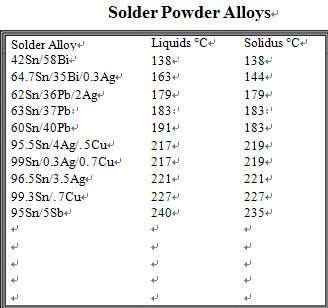

Alloy Composition:BBIEN’s powders are produced using only the highest quality virgin materials. All our powders exceed the J-STD-006 specification.

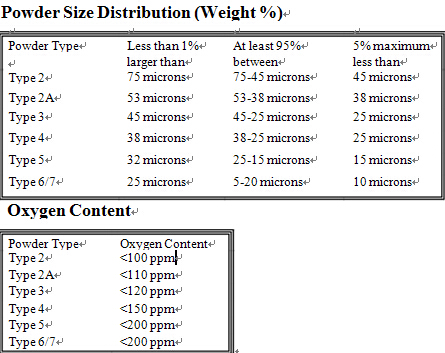

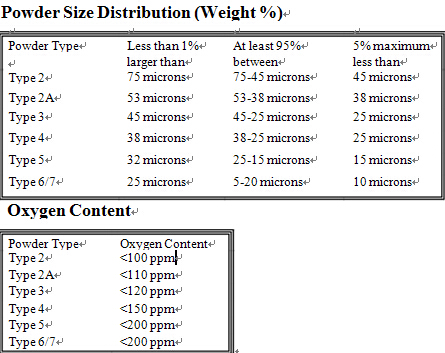

Oxygen Content:All BBIEN solder powders are atomized in a controlled atmosphere to minimize oxygen content. Typical values for 63Sn/37Pb are listed below.

Solder powders are the key component of all solder pastes. Pastes made with the same flux but with powders that differ in particle sizes often have different rheological/physical properties resulting in differences in screen/stencil printing, component placement and production yields. The powder constituent of solder paste, in fact, affects all stages of surface mount assembly from stability and printability of the paste, to the quality of the final fillet.

Normal composition of BBIEN's solder powder

|

SMT solder powder |

melting point °C |

Type no. |

Application |

|

Sn63Pb37 |

183 |

Type2-4 |

PCB |

|

Sn96.5Ag3.5 |

222 |

Type2-5 |

SMT,cellphone component |

|

Sn96.5Ag3.0Cu0.5 |

217 |

Type2-7 |

SMD、SMT

LED、PCB |

|

|

|

Sn99.0Ag0.3Cu0.7 |

|

Sn64Bi35Ag1 |

179 |

Type2-4 |

SMT,PCB |

|

Sn64.7Bi35Ag0.3 |

179 |

Type2-4 |

LED |

|

Sn42Bi57.6g0.4 |

179 |

Type2-4 |

LED |

|

Sn62Pb36Ag2 |

183 |

Type2-5 |

SMT,PCB |

|

Sn42Bi58 |

138 |

Type2-4 |

LED |

Special size such as Sn96.5Ag3.0Cu0.5 silver solder powder can supply type 6(15~20micron); and type 7(5~12micron).

Other special solder powder:

|

合金成份 |

Melting point(℃) |

|

Sn99Ag0.3Cu0.7 |

217-221 |

|

Sn98.5Ag1Cu0.5 |

221-221 |

|

Sn96.5Ag3Cu0.5 |

217-217 |

|

Sn95.7Ag3.8Cu0.5 |

217-219 |

|

Sn95.5Ag3.8Cu0.7 |

217-219 |

|

Sn95.5Ag4Cu0.5 |

217-219 |

|

Sn96.5AG3.5 |

211-221 |

|

Sn99Cu1 |

227-227 |

In response to the power semiconductor market's drive to improve reliability and device performance for automotive, alternative energy, transportation, consumer electronics, telecommunications and industrial applications.

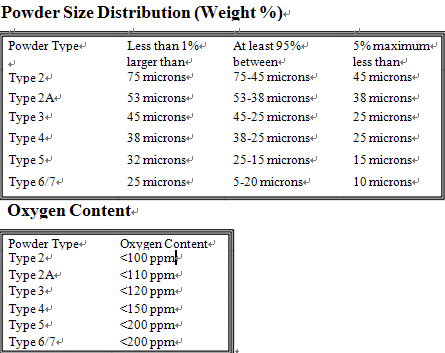

Powder size

|

Type2(45-75um) |

≤120ppm |

≤0.08% |

|

Type2.3(38-63um) |

≤120ppm |

≤0.08% |

|

Type3(25-45um) |

≤120ppm |

≤0.08% |

|

Type4(20-38um) |

≤120ppm |

≤0.1 % |

|

Type5(15-25um) |

≤180ppm |

≤0.15% |

Packaging:All BBIEN powder is packaged in 5kg metallized mylar bags under inert gas. 20 or 25 kg per plasitic case/barrel.

FIVE bags are packed in sealed polyethylene containers to prevent damage.Alternative packaging is available to satisfy customer requirements.

The picture up is 25kg/barrel packing,while the down is 5kg/bag

Facility Capacity:

Facility Capacity:BBIEN’s powder facility is capable of producing 2000~100,000 kg of finished solder powder per Month.

Certificate of Analysis:All BBIEN powder is delivered with a detailed CofA including

chemical analysis and image analysis size distribution. Coullter particle distribution available upon request

Shipping by:TNT,UPS,EMS,airway shipping